Project Background

Various semiconductor materials and devices have been widely applied in aerospace vehicles, the medical field, and nuclear control systems. However, these microelectronic devices face challenges in strong radiation environments, such as space radiation and artificial radiation. Radiation affects their reliability and may lead to the failure of some or even the entire electronic system.Therefore, research on the radiation and radiation resistance performance of semiconductor materials and basic components would be required to ensure that these special microelectronic devices can work stably in harsh radiation environments.

Meanwhile, X-rays can penetrate substances and provide information about their internal structure and composition. Compared with common ionizing radiation of the same energy, X-rays are concerned more difficult to be shielded and will bring harm to the human body. Accordingly, it is particularly important to establish a safe, reliable, and multi-functional probe station system for X-ray irradiation testing of semiconductor electronic devices.

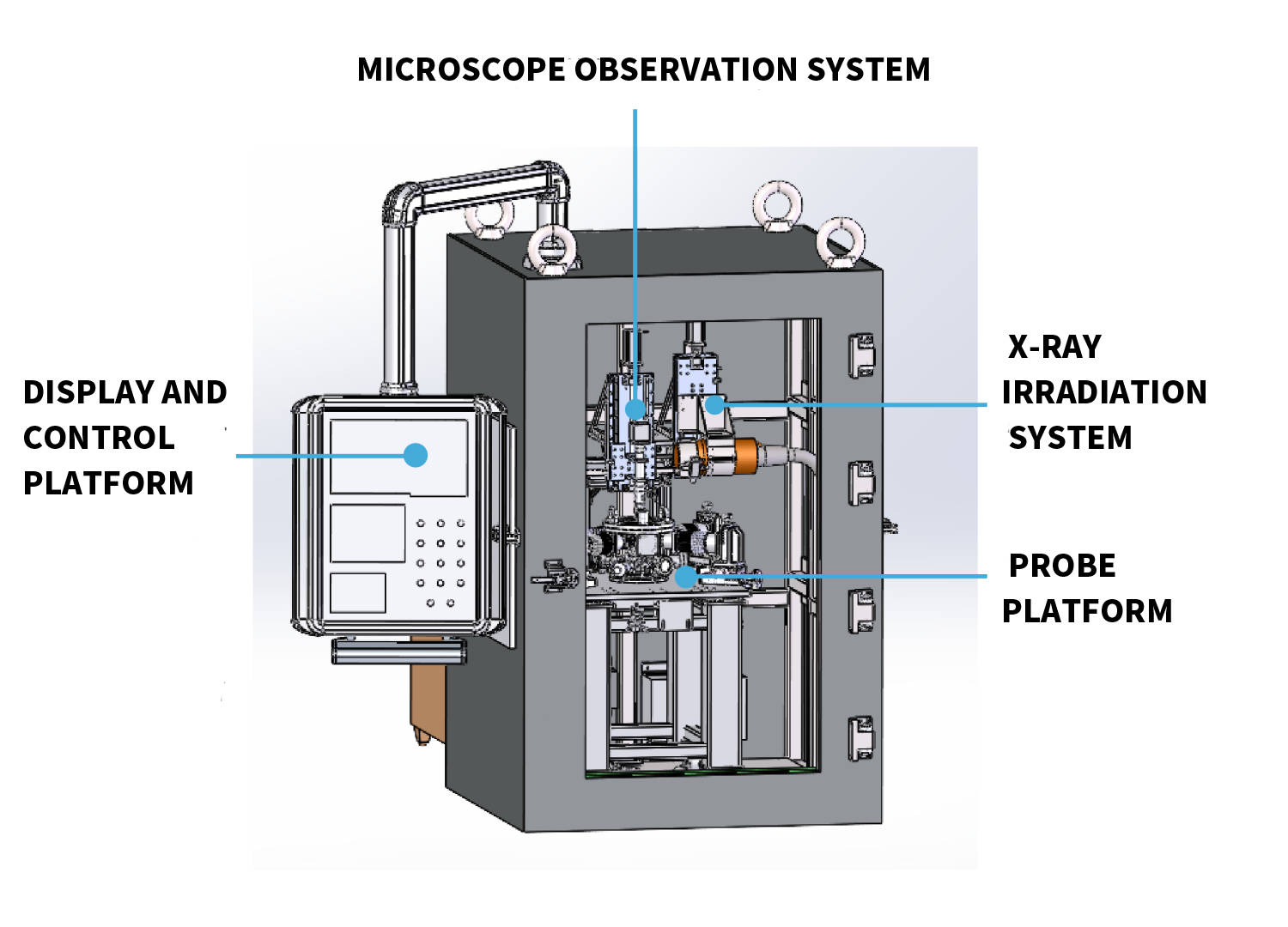

Integration Configuration

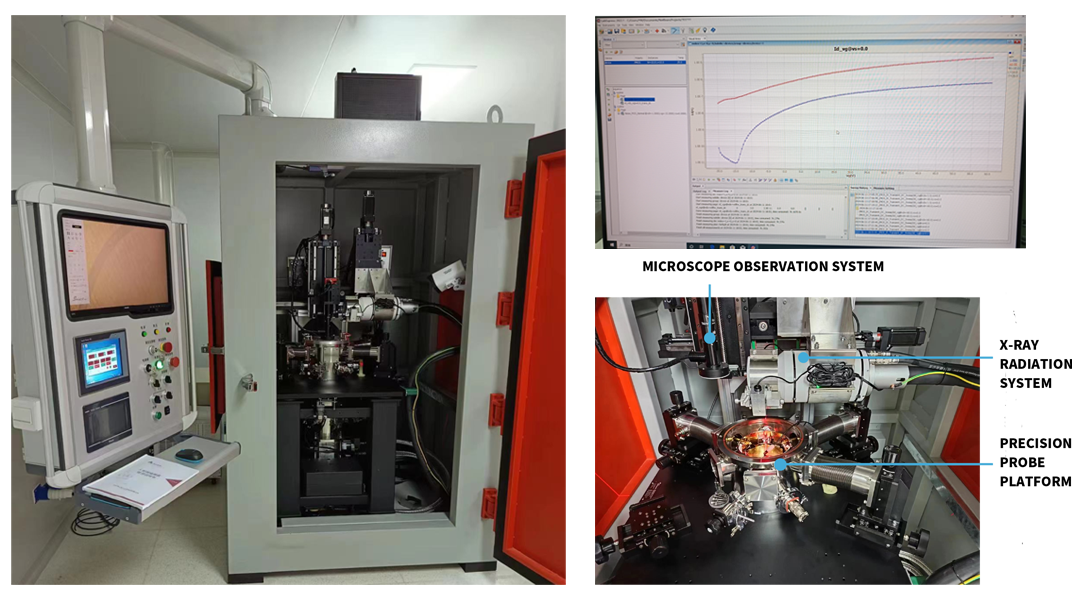

SEMISHARE Semiconductor X-ray Test Probe Station integrates the X-ray radiation system (including X-ray generator with high-voltage power supply and filament heating power supply, X-ray controller, X-ray tube, and water cooling system), probe station system (precision probe platform, low-light imaging system, stable shock-proof system), optical imaging system, and software automation control system organically. This integration is achieved through multi-axis electric motion, enabling sequential high-stability micro-probing and X-ray irradiation.

Case of Integration Configuration

Highlights

SEMISHARE has self-developed various models of probe stations, which can be configured with multiple test environments such as high temperature, cryogenic temperature, and vacuum.

✓ High-precision diffraction angle test system to obtain more accurate test results;

✓ High-stability X-ray generator control system to achieve more stable repeated accuracy;

✓ Programmed operation and integrated structure design, easy to operate and more attractive appearance;

✓ Flexibly movable display and control platform for convenient and multi-directional needle-piercing actions;

✓ Special shielding box to prevent X-rays from harming operators;

✓ Simple operation and convenient adjustment. The radiation dose rate can be precisely controlled through setting up the parameter in the panel with large adjustable range.

✓ Good equipment safety,the radiation around the instrument is the same as that in the ordinary environment;

✓ Supporting freely integrates various devices generally includes stretching and traction, laser vibration test, laser cutting, X-ray and γ-ray radiation etc., which can provide a perfect and reliable test platform for research and testing in special fields.